Sponsored By

Medical

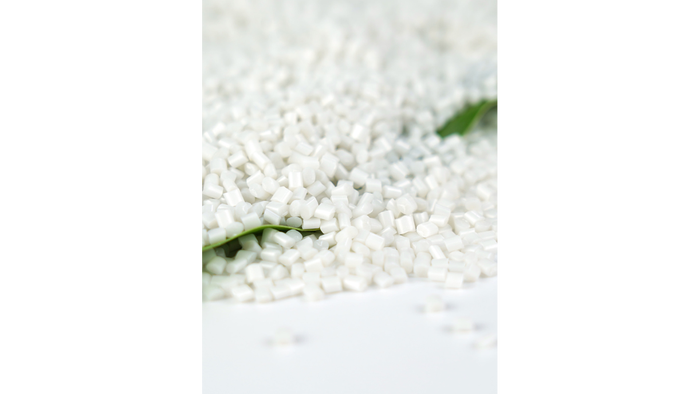

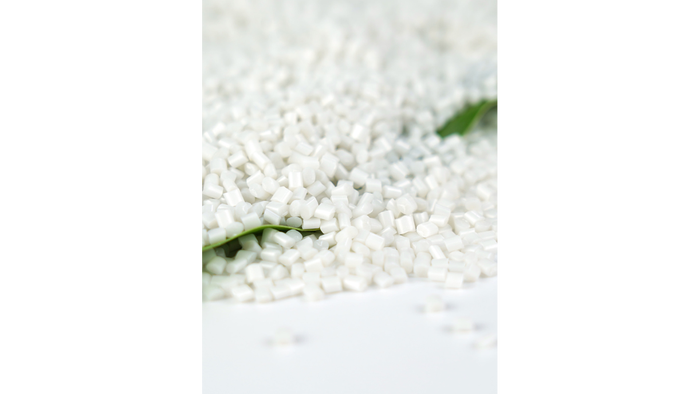

compostable plastic resin

Medical

Formerra Begins Selling ISCC PLUS–certified MaterialsFormerra Begins Selling ISCC PLUS–certified Materials

The healthcare industry is leading demand for biobased feedstocks because of concern over contamination using recycled-content materials, said the company at NPE.

Sign up for the PlasticsToday NewsFeed newsletter.

[42].jpg?width=700&auto=webp&quality=80&disable=upscale)