Sponsored By

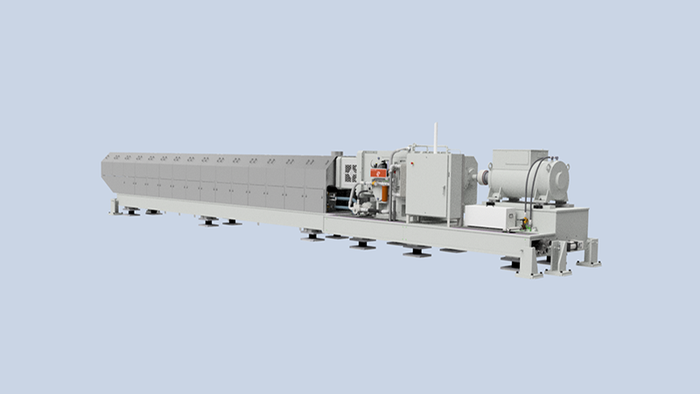

Extrusion: Pipe & Profile

plastic tubing

Automotive & Mobility

NYCOA to Launch Plasticizer-free Long-chain Polyamide PortfolioNYCOA to Launch Plasticizer-Free Long-Chain Polyamide Portfolio

NXTamid L is equivalent in performance to PA 12, but offers sustainability advantages.

Sign up for the PlasticsToday NewsFeed newsletter.