Sponsored By

Medical

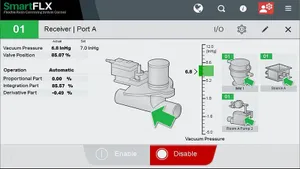

part of the circularity demo system

Medical

How to Transform a Medical Vial Into a Bottle OpenerHow to Transform a Medical Vial Into a Bottle Opener

KraussMaffei’s magic trick on the NPE show floor is a stunning example of circularity.

Sign up for the PlasticsToday NewsFeed newsletter.