Sponsored By

Injection Molding

Mobile Manipulator

Automation

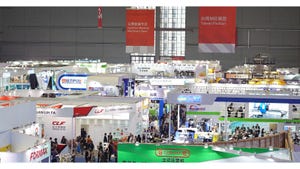

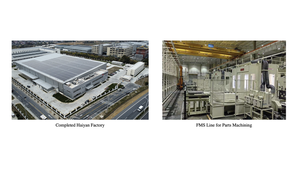

Automation for Plastics Processors Is on the Move at Muller TechnologyAutomation for Plastics Processors Is on the Move at Muller Technology

The company is bringing its new mobile manipulators and autonomous mobile robots to NPE2024.

Sign up for the PlasticsToday NewsFeed newsletter.

.png?width=300&auto=webp&quality=80&disable=upscale)